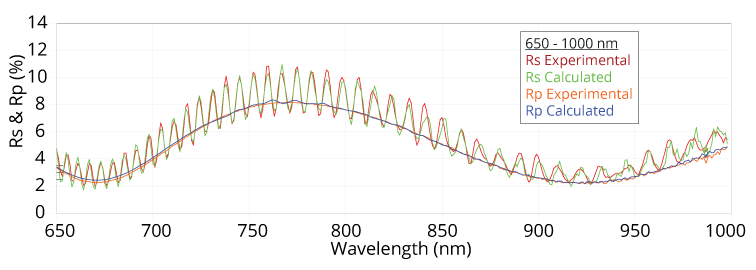

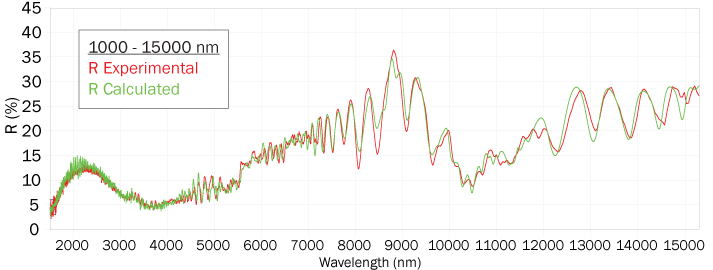

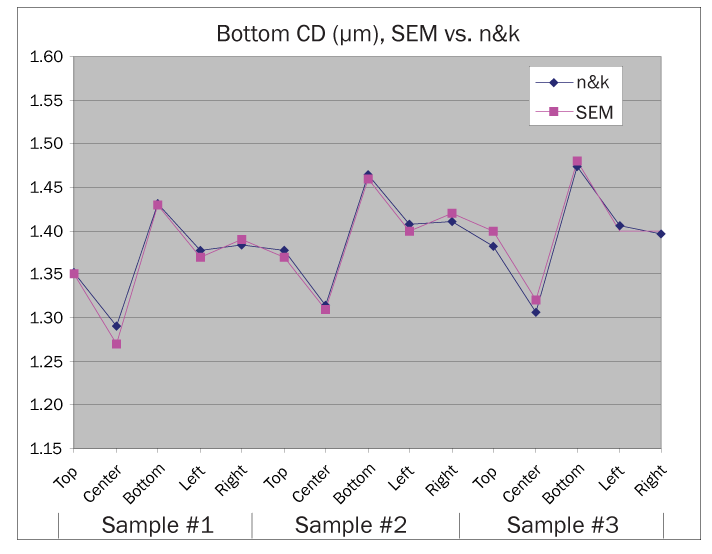

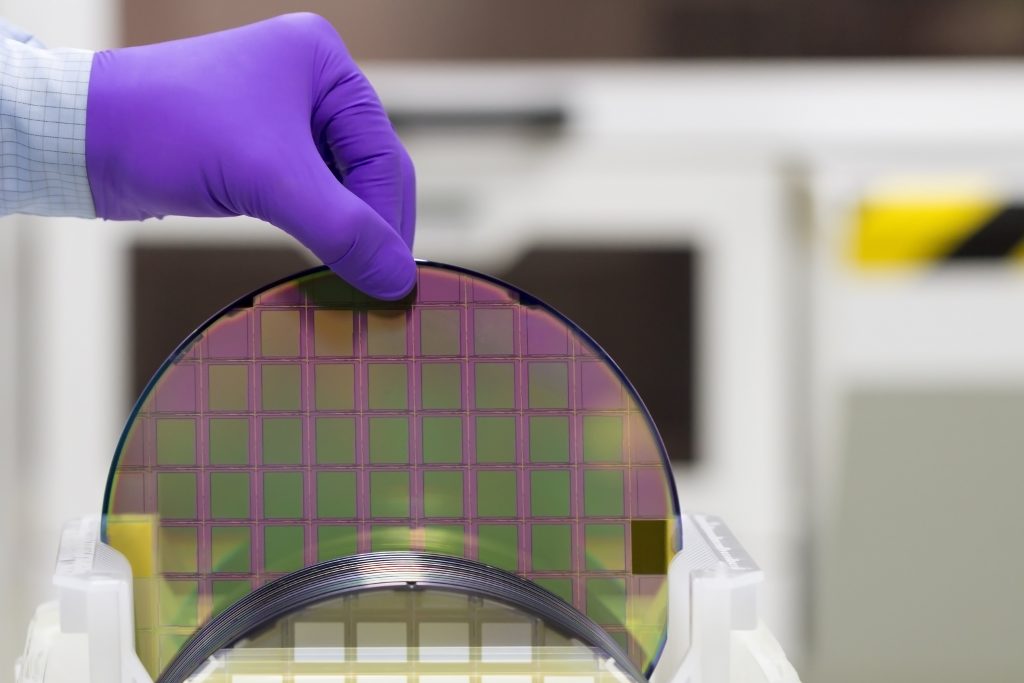

Utilizing patented all-reflective optics, a broadband wavelength range (190 – 15,000nm), proprietary optical formulation, and an industry leading signal-to-noise ratio, each system provides the accurate and reproducible data required to monitor subtle changes in critical device parameters (thin film thickness, optical properties, critical dimensions (CD), poly recess profile, sidewall angle) across various key applications.